Down Hole Motors

Down Hole Motors

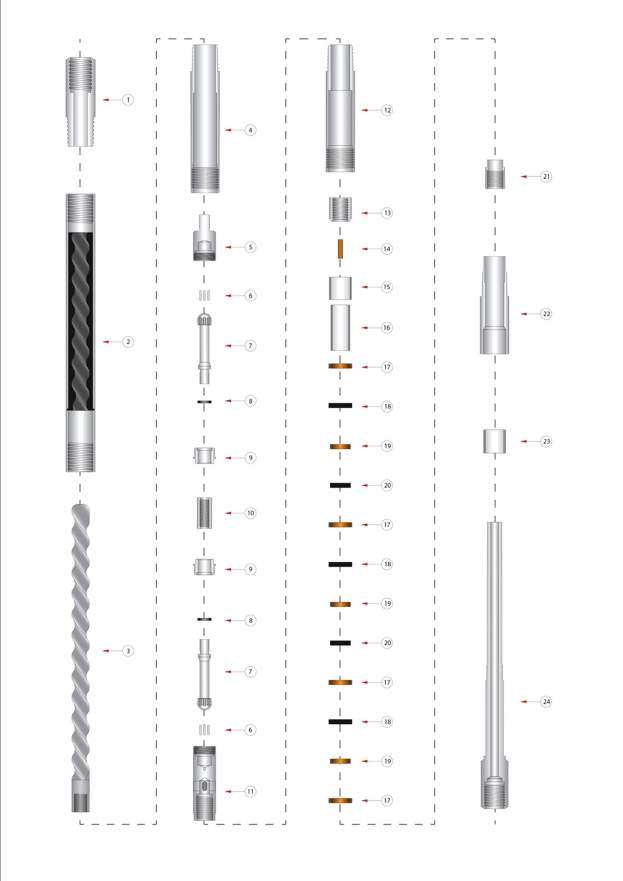

Asahi supplies Down Hole Motors commonly used for directional drilling in coal and hard rock mining as well as civil construction. They are also used as an alternative to conventional deflection style drilling where wedges are used.

The Down Hole Motor is driven via fluid pumped into the motor, which then turns it into a mechanical rotary motion through the form of a rotor. This rotary motion is applied to a Drill Bit (either PCD, impregnated diamond) and attached to the end of the motor to cut into the formation being drilled.

The direction of the motor can be determined by a “bent sub”. These subs can be fitted to the DHM to adjust the “angle” of the motor and how fast it can turn within the hole.

Asahi stock bent sub’s in standard angles - 1 degree, 1 ½ degree and 1 ¼ degree.

Many of our mining products can be re-tipped, refurbished and repaired at our Sydney factory. Click here for more information.

Tool Sizes |

2 3/8 |

2 7/8 Becu |

2 7/8 Steel |

|---|---|---|---|

| Diameter (inches) | 2.375 | 2.875 | 2.875 |

| Lobes | (5-6) | (4-5) | (5-6) |

| Stages | 2.5 | 3 | 4 |

| Length (ft) | 9 | 9.5 | 11 |

| Weight (lbs) | 140 | 160 | 180 |

| Top Connection | BW | NW | NW |

| Bit Connection | BW | NW | NW |

| Make Up Torque (ft/lbs) | 600 | 1200 | 1200 |

| Bit Sizes (inches) | 2 7/8 - 3 1/2 | 3 1/4 - 4 | 3 1/4 - 4 |

| Max Weight on Bit | 3500 | 6000 | 6000 |

| Max Bit Pressure Drop (psi) | 200 | 200 | 200 |

| Minimum Flow Rate (gpm) | 25 | 30 | 40 |

| Maximum Flow Rate (gpm) | 50 | 70 | 80 |

| Recommended Flow Rate (gpm) | 42 | 60 | 70 |

| Bit Speed (rpm) | 200 - 375 | 160 - 375 | 250 - 450 |

| Pressure Drop at Max Torque (psi) | 400 | 400 | 495 |

| Max Operating Torque (ft/lbs) | 130 | 190 | 225 |

| Maximum Overpull (lbs) | 12500 | 20000 | 20000 |

|

Asahi Down Hole Motors aren't currently available to buy online. |

|---|